| Author | Message | ||

| Charles I Claussen (Atlantaman)

Junior Member Username: Atlantaman Post Number: 174 Registered: 3-2002 |

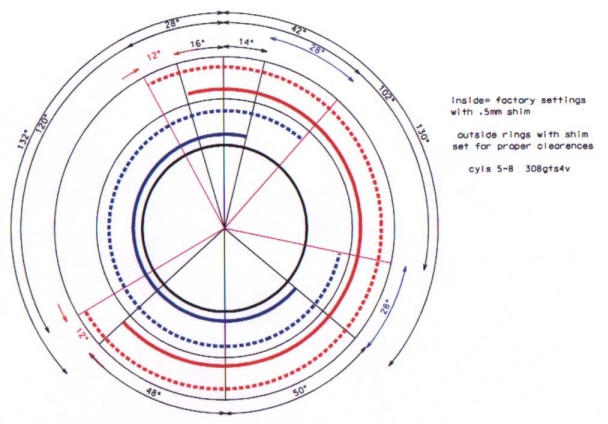

I borrowed one to do my motor originally then while playing with it--thought I had slipped a belt ... thats when I cam up with the wild method that I posted. Everything came out good... OK more info... I will re-post my chart here BUT--keep in mind the critical part is that you NOT get the same numbers(because shims may be .0005 off from mine) but that your numbers are the same above and below your factory specs--symetrically--so to speak. Note for example on the graph that 28 and 12 degrees are symetrical ...  | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 787 Registered: 5-2001 |

Here's the thread Charles is referring to: http://www.ferrarichat.com/discus/messages/112/17479.html I dug it up a couple of days ago for the "308 Cam specifications: European ?" thread. BTW, Charles, could you please take a look at the above thread? Tom is getting some vy strange cam timing measurements when measuring at the 0.5mm valve clearance (ie: cam bearing cap movement) points. That method should produce identical results to using the 0.5mm shim. BTW, where can I buy a 0.5mm shim? | ||

| Charles I Claussen (Atlantaman)

Junior Member Username: Atlantaman Post Number: 169 Registered: 3-2002 |

Mick, If you search old posts from last spring you will find a helpful chart that I drew on setting the cams WITHOUT REMOVING VLAVE COVERS. if you are verrrrry careful you can put about 10 psi into the sparkplug hole, and rotate the cam. remove the plenum and put an ear to the intake and to the exhaust port --stethescope comes in really handy here-- IMPORTANT PART*****--the degree on opening and closing will be different from what is published because you are not using the desired .5mm shim. the CAD chart I posted is very close for the new degree marks.. the most critical part is to be sure that you see the same change on opening--IE. if the valve opens 10degree before normal then it should close 10degree after normal.--and PS when I also had my motor out of the car and set them in the traditional way--my new way was dead on!! and the timing marks were about 5 deg off on all 4. | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 776 Registered: 5-2001 |

Mick, You might say: 'Luck O' th' Irish'... Know all about the suspense. When I was doing my timing gear rebuild last spring, I thought I'd tapped a valve w/a piston. Somewhere in the archives there's a panicky post... Luckily all I'd done was take all the slack out of my drive train. I had the car in gear w/the park brakes locked. The gear lash still gives you about 10 degrees of engine rotation lock-lock. Once I knew the slack was there, it came in handy for belt installation & cam gear timing. | ||

| Mick Worrall (Catswhiskers)

New member Username: Catswhiskers Post Number: 10 Registered: 4-2003 |

Hi Verell, Couldn't bear the suspense any longer. Spent the last few hours putting everything back together and cranking by hand before fitting plugs. Happy to say that engine started on first turn of the key. I left it to run on idle for 5 minutes before playing with the throttle. What a relief, engine up to temperature, it revs crisply and without hesitation, and pulls in all gears as smooth as it ever did. I'll get a compression check at the weekend just for piece of mind but I'm happier than I was a couple of days ago. Thanks again. Mick | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 773 Registered: 5-2001 |

Mick, The important checks for 'non-bent valves' are: - Does the valve seal properly. - Does it slide freely in the guides. Much easier to check while things are apart, especially before the cam springs are installed. Otherwise you have to resort to compression, & leak-down tests to be sure. A couple of quick checks are: 1) See if the valves all work smoothly when you press them down. 2)Put 5psi on each cylinder while it's at TDC & see if you can hear hissing. If all is smooth & quiet then you're probably OK enough to try running the engine until it's warm enough for a leakdown test. | ||

| Mick Worrall (Catswhiskers)

New member Username: Catswhiskers Post Number: 9 Registered: 4-2003 |

Actually guys, I did find the timing marks Peter's photo shows. But they aren't very deep. Once I'd wiped the oil off and dried the cam, there they were. The inlet cam had actually slipped 3 teeth (later in cycle) so by my reckoning, it had gone the safe way. In other words, opened the valve several degrees later and as such, the inlet valves did not come in danger of hitting the pistons. I haven't finished re-building things yet but as a check, the valve clearances all check out OK. This wouldnt be the case with bent valves would it? I hope to get things back running by the weekend ready to fit my new stainless exhaust system. (watch for forthcoming pictures and comments) Thanks again for all the help. Mick | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 769 Registered: 5-2001 |

The shop manuals show the cams as being marked in 2 places: 1) A mark on a flat ground at an angle on the back side of the cam gear mounting flange - This is what Ben is describing. 2) The more precise mark that aligns with the mark on the bearing cap as in Peter's photo. My '82 Euro 308 GTS QV engine has both sets of marks on all 4 cams. I keep forgetting about the ones on the back of the cam gear flange as they are too dicey to use. | ||

| Steve (Steve)

Member Username: Steve Post Number: 380 Registered: 2-2001 |

Ben do you have any pictures? My 77 setup is just like Peter's. | ||

| Ben Millermon (Brainsboy)

Member Username: Brainsboy Post Number: 321 Registered: 5-2001 |

Mick for what its worth, I have an 81GTSI also. My cams do not have the markings in the same spots as peters photo here. Peters may be a different year. My markings can be viewed without removing the valve cover, its a notch right behind where the belt pulley attaches to the cam. Also as a note, be damn careful setting the cams. I set my cams with the motor out, once I installed the motor and look at the front bank, I swear it looked as if the cams where a tooth off. I actualy had it right, but looking at it through an angle is not good, you can easily think its correct but be off. Just my 2 cents worth. | ||

| Steve (Steve)

Member Username: Steve Post Number: 378 Registered: 2-2001 |

Verell are you sure that the cam bearing nuts are 6.5 lb. ft (78 lb. in) . My large torque wrench doesn't go that low but my small one does lb. in. So unless the conversion is wrong this seems like a large number. I know if I check another cap that was not touched I can move it at 25 lb in. Do I have this wrong here? | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 752 Registered: 5-2001 |

0.9 Kg-M (6.5 Ft-lb) - same as other 6x1 nuts such as the cam cover nuts. | ||

| Steve (Steve)

Member Username: Steve Post Number: 375 Registered: 2-2001 |

I'm in the process of redoing the belts and the valve adjustment.I had to use the matchcover under the cam proceedure. Only did 1 belt tonight will do the other tomorrow. I used my old volvo process by aligning to 1-4 cam marks lined up. Marked belt with whiteout and marked all 3 pulleys. Removed tensioner asm. and removed belt.Marked new belt and cleaned and installed new tensioner. Put belt on and aligned marks and held belt using 4 clothspins (spring type). Installed tensioner asm. in closed position. Released tensioner spring and tightened.Remove matchcovers and retighten cam bearings (WHAT IS THE TORQUE FOR CAM BEARING CAPS?)and rotated crank 2 turns. Timing marks were perfect. | ||

| Verell Boaen (Verell)

Member Username: Verell Post Number: 745 Registered: 5-2001 |

Mick, Been there, done that. Sure a sinking feeling in the pit of your stomach when it happens tho, isn't it.... The Euro 308s, 208s, & 328s all have cam marks. Could you be on the wrong crank rotation? Remember that it's a 4-cycle engine, so the cam marks only line up every other rotation of the crankshaft. On alternate rotations, when the crank is on PM1-4, the cam marks are pointing down towards the crankshaft's centerline. re:"is it possible to set both cams so that inlet and exhaust valves are closed on No.1 and 4 then rotate engine to TDC" Yes, If you're in fact coming up towards the PM1-4 mark (TDC)on the correct rotation, you can setup the cams as you describe, lock them into place, and very carefully & very very slowly bring the engine into position. Pull the spark plugs 1st so you aren't fighting any compression & have maximum control. If you're on the opposite crank rotation, then you have to decide how certain you are that you only slipped 1 or at most 2 teeth on the cam drive gear. If you're positive that's really all you slipped, then you can safely rotate the engine into the proper alignment, with the belt driving the cams. Again, very very very slowly. You are taking a risk that it slipped more teeth than you think. If I remember the 308 timing wheel correctly, 3 teeth (36 degrees) of cam miss-timing in the wrong direction is unsafe and you will tap a valve. If there's any doubt whatsoever, about the cam's timing, or your ability to precisely control engine rotation, then it's time to pull the cams until you've got the engine properly lined up on PM1-4. Heresay (and maybe a couple of ancient posts) has it that people have accidently tapped a valve with a piston while rotating a 308 engine by hand, without any more damage than needing fresh underwear afterwards. I think Ric Rainbolt once admitted to doing it, or maybe it was just someone he knew. I've done it on a Jag XK-150, but not on a 308. I've elected to pull the cams when my cam belt jumped a tooth or two (or possibly 3...). | ||

| Mick Worrall (Catswhiskers)

New member Username: Catswhiskers Post Number: 8 Registered: 4-2003 |

Doen't get any easier does it. I removed the cam cover today and the cam belt cover. Rotated the engine to check alignment of marks and guess what, no marks on cams. Is it possible that European cams have different markings? Anyhow, while contiuing to rotate engine by hand, in frustration I forgot I'd slackened the tensioner pulley ready to adjust. Cam belt slipped again so I stopped immediately. Engine is now approx. 15 degrees BTDC but I think on No4 firing stroke. Not wanting to bend any valves, is it possible to set both cams so that inlet and exhaust valves are closed on No.1 and 4 then rotate engine to TDC ? What an amateur eh. Help. | ||

| Ted Gage (Tedmac)

New member Username: Tedmac Post Number: 4 Registered: 2-2003 |

I strongly suggest using a degree wheel to verify cam setting. I'm in the process of rebuilding my 308 and I found the factory index mark to be off an entire tooth (12 degrees on the timing gear and 24 degrees on the crank). There are also 5 holes in the timing gear, and 4 holes in the cam allowing incremental adjustment between timing gear teeth. The first thing to do is to align things as in the picture and see if the timing is correct. | ||

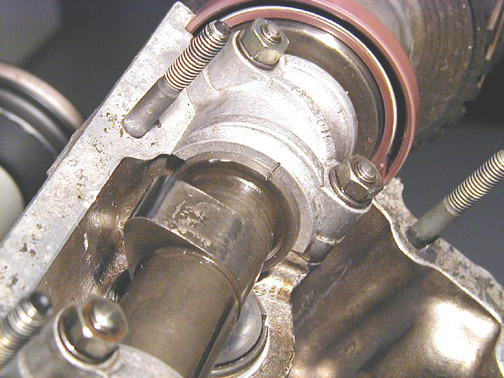

| '75 308 GT4 (Peter)

Advanced Member Username: Peter Post Number: 2763 Registered: 12-2000 |

Here's what it looks like inside:  The mark on the cam lines up with a mark on the cam-bearing cap. | ||

| Mick Worrall (Catswhiskers)

New member Username: Catswhiskers Post Number: 7 Registered: 4-2003 |

I've just replaced the cam belts and tensioner pulleys on my '81 308GTSi. All went OK but I suspect that the rear bank inlet cam has slipped a tooth on the belt. Before I remove the cam cover to check, can someone please post a photo or photos of the timing marks on the cam and the corresponding marks they line up with on the head or elsewhere. Just so I know what to look for and where to look. Thanks guys. Mick. |